Component Pressure Testing Systems

Curtis Assemble & Test Ltd specialise in the design and manufacture of high-pressure component testing systems. Our machines generate controlled fluid pressures for a wide variety of applications, including cleaning, validation, and component integrity testing.

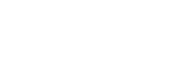

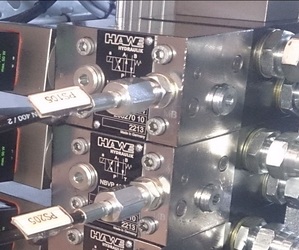

Depending on application requirements, pressure can be generated using different techniques. The most common are multi-piston pumps and oil-oil intensifiers, both of which are proven methods used in many of our high-pressure test machines.

Flexible Test Media

In addition to hydraulic oil, we also design systems capable of testing with air, nitrogen, and water. Each test medium requires specific procedures and techniques, which our experienced team evaluate carefully to ensure accuracy, repeatability, and efficiency. This expertise allows us to provide the right solution for your pressure testing application, regardless of the fluid medium required.

Pressure Generation Capabilities

⚙️ Pressure: up to 3000 bar

⚙️ Pressure stability: better than ±0.1 bar for steady state conditions

⚙️ Flow rate: up to 100 l/min (depending on pressure)

⚙️ Temperature control: up to 160°C ±1°C (depending on fluid)

With decades of expertise in component pressure testing, Curtis Assemble & Test Ltd deliver bespoke high-pressure solutions designed to meet your exact requirements. Contact our team today to discuss your application and testing needs.