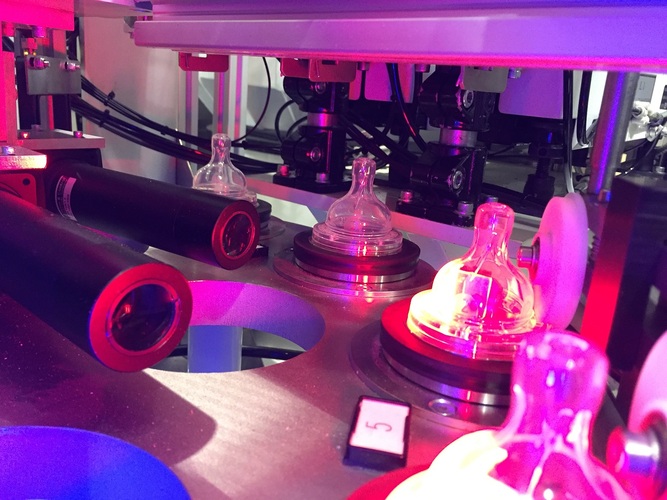

Vision Inspection Systems for Automated Quality Control

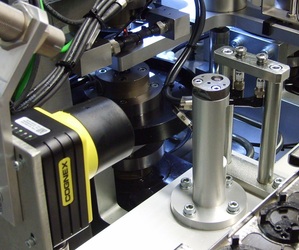

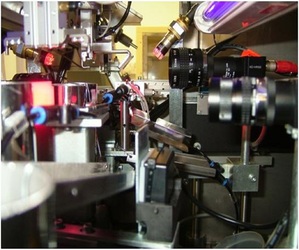

Curtis Assemble & Test Ltd has been integrating vision inspection systems for over 25 years, working with leading manufacturers across a wide range of industries. Vision systems are a vital tool in modern manufacturing, enabling automated inspection, quality control, and traceability at every stage of production.

Our experience allows us to design and integrate bespoke systems that meet specific customer requirements — whether part of new automated machinery or retrofitted into existing equipment.

Applications of Vision Inspection Systems

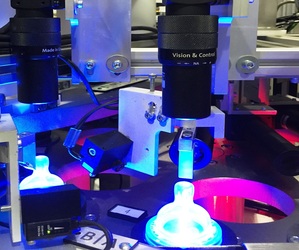

✔️ Dynamic analysis of injection spray patterns

✔️ Dimensional analysis and measurement

✔️ Presence/absence detection of parts or features

✔️ Parts counting and verification

✔️ Quality inspection and defect detection

✔️ Leak detection support

✔️ Part traceability and tracking

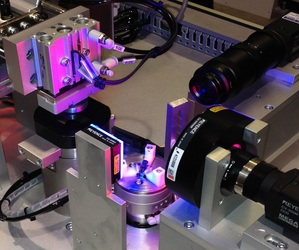

Lighting & Integration Expertise

One of the most critical aspects of a successful vision inspection system is achieving the right lighting conditions. Poor lighting can result in inconsistent results, especially when retrofitting systems to existing equipment. With decades of experience, CAT provides the expertise to overcome integration challenges and ensure reliable, repeatable inspection performance.

Part Traceability

Our systems enable manufacturers to trace each component throughout the production process and track it once integrated into assemblies. This provides greater visibility of manufacturing quality and the performance of finished products. Problems identified during functional tests can be traced back to individual components, whose full production history is available for review.

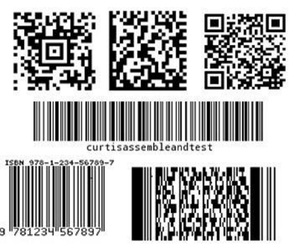

Traceability in Action

CAT’s traceability solutions often use data matrix codes, barcodes, or RFID tags to mark parts with unique identifiers. Each time a process is performed, the code is scanned and logged in a central system. This ensures:

✔️ A complete history of operations for every component

✔️ Full integration with assembly records

✔️ Easy retrieval of manufacturing data for audits or troubleshooting

✔️ Verification that all required steps are complete before further work is carried out

This level of traceability helps prevent costly errors, reduces waste, and improves overall product quality.

With over 25 years of experience in vision inspection system design and integration, Curtis Assemble & Test Ltd delivers reliable solutions that improve quality, reduce defects, and enhance traceability. Contact us today to discuss a tailored vision inspection solution for your production line.