Cleaning in Place (CIP) Systems

Curtis Assemble & Test Ltd design and manufacture Cleaning in Place (CIP) systems for reliable, automated cleaning of components during or after production. Our CIP modules are trusted by manufacturers worldwide for pre-operation gauging and post-operation cleaning, helping to ensure compliance with cleanliness standards and improve long-term equipment performance.

Core Features of Our CIP Systems:

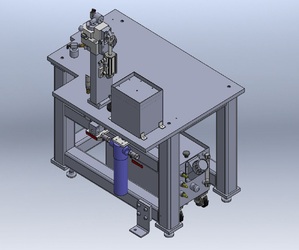

⚙️ Power Unit – fluid reservoir with pump motor, valve manifold for fluid diversion, and inline filtration for continuous cleaning

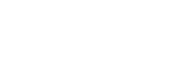

⚙️ Fixture – custom-designed enclosure with top access for auto-loading and ports for both wash fluid and drying air

⚙️ Drain & Dissipation Tank – sealed tank with filter foam to return fluid to the reservoir and minimise foaming during drying

⚙️ Electrical & Software Control Enclosure – hardware for wash and dry sequencing, with option to link to the host machine’s prog

Why Choose CAT CIP Systems?

✔️ Precision cleaning in demanding production environments

✔️ Seamless integration with new or existing equipment

✔️ Reduces downtime and improves reliability

✔️ Backed by decades of engineering expertis

Our Cleaning in Place (CIP) systems deliver consistent, high-quality results for manufacturers worldwide. Contact us today to discuss how a bespoke CIP solution can support your production line.