Hydraulic and Pneumatic Leak Testing

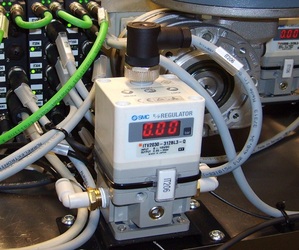

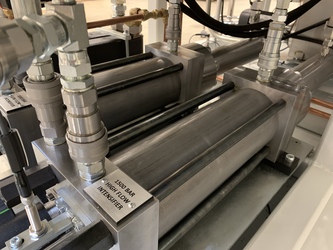

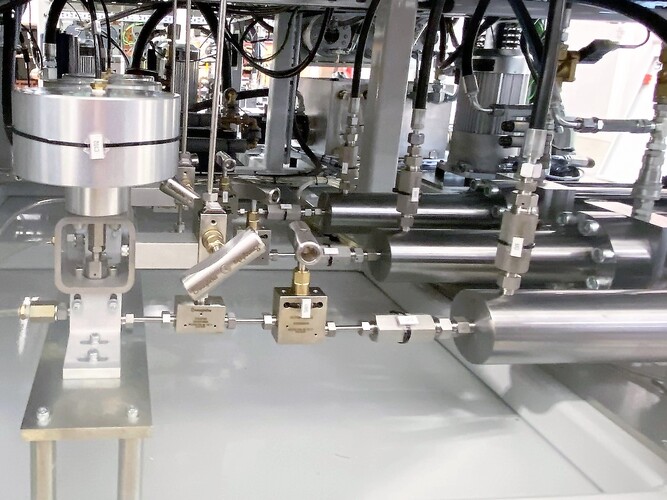

Curtis Assemble & Test Ltd design and manufacture high-pressure test machines for hydraulic and pneumatic leak detection. Our systems are used to measure internal and external leaks in components, ensuring performance, safety, and compliance across industries.

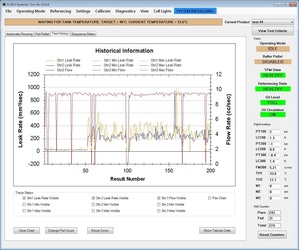

We build bespoke test machines tailored to your requirements. Using flow meters, pressure chambers, and transducers, our systems accurately detect leaks, record pressure rise or decay, and deliver reliable results in line with your specifications.

Our machines are capable of testing at pressures up to 3000 bar for hydraulic systems and 250 bar for pneumatic systems. Whether you need to validate seals, monitor performance over time, or ensure compliance with international standards, we provide solutions that guarantee accuracy and repeatability.

Integrated Vision Systems:

For complex components where leaks are visible externally, our vision systems detect changes in pixels around the leak area, providing a reliable, non-contact inspection method.

Leak Detection Capabilities:

⚙️ Test pressure: 70 mbar to 3000 bar

⚙️ Temperature range: ambient to 60°C (higher options available)

⚙️ Flow range: 0.01 cc/min to 20 cc/sec and higher

⚙️ Cycle time: from 10 seconds

⚙️ Evaluation criteria: pressure change over time (pressure decay / pressure rise), timed pressure drop, measured flow (flow measurement / mass flow), blob growth

⚙️ Media: air, hydraulic oil, calibration fluid, water

Our hydraulic and pneumatic leak testing systems are trusted by global manufacturers to deliver precision and reliability. Contact us today to discuss a bespoke solution for your business.