Automated Gauging & Measurement

Accurate measurement and gauging are essential in modern manufacturing. Whether you need to periodically check sample components or measure every single part on your production line, Curtis Assemble & Test Ltd (CAT) provide automated gauging solutions that deliver reliable, repeatable, and traceable results.

With decades of experience, we have successfully integrated precision gauging systems into bespoke machines across multiple industries, ensuring our customers maintain compliance with the strictest quality standards.

Why Automated Gauging Matters

Automated gauging eliminates human error and delivers:

⚙️ Consistent measurement accuracy across all parts

⚙️ Faster cycle times compared to manual inspection

⚙️ Full traceability through digital data capture and reporting

⚙️ Reduced scrap and rework by detecting defects early

⚙️ Improved efficiency through integration with automated production lines

Gauging & Measurement Technologies

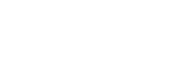

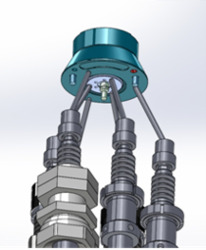

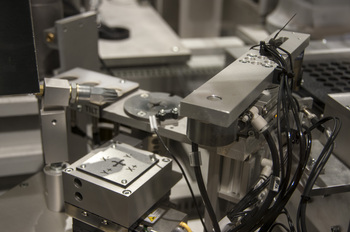

CAT design and integrate gauging systems using a wide range of world-class technologies to suit each application:

✔️ Laser Micrometers – for non-contact, high-precision external dimension measurement

✔️ Air Gauges – for internal diameter checks and complex bore measurements

✔️ Contact Probes – for tactile measurements where precision contact is required

✔️ Optical & Vision Systems – for component inspection and surface feature measurement

✔️ Specialist Sensors – including Mitutoyo, Marposs, Keyence, and Micro-Epsilon technologies

We carefully select and configure the right measurement technology based on your product geometry, required tolerances, and production environment.

Example Applications

Our gauging systems have been used to measure:

⚙️ Automotive components such as gears, injectors, and housings

⚙️ Aerospace parts requiring ultra-tight tolerances

⚙️ Hydraulic and pneumatic components

⚙️ High-volume plastic injection moulded parts

⚙️ Precision medical and electronic devices

Partnering With CAT

From standalone gauging stations to fully integrated automated inspection systems, CAT tailor solutions to your requirements. Our expertise ensures:

✔️ Reliable compliance with international quality standards

✔️ Seamless integration into new or existing production lines

✔️ Bespoke system design backed by in-house mechanical, electrical, and software engineering

✔️ Comprehensive support from concept through to commissioning