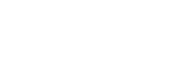

Liquid & Air Flow Measurement Systems

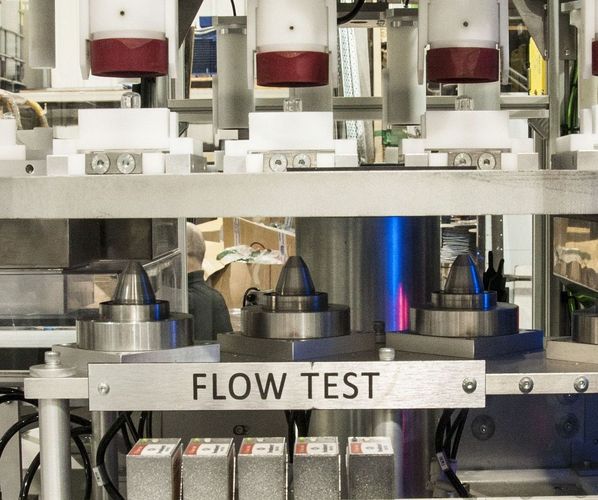

Curtis Assemble & Test Ltd (CAT) specialise in the design and manufacture of flow measurement systems for both liquid and air applications. Our solutions are used to verify the performance of manufactured parts across industries including automotive, aerospace, defence, and high-volume precision engineering. From dosing control to full component evaluation, our systems deliver accurate, repeatable results tailored to customer requirements.

Expertise in Flow Testing

Accurate flow measurement requires careful control of many factors, including:

⚙️ Test medium and component temperature

⚙️ Test fluid supply pressure

⚙️ Back pressure applied to the component

⚙️ Viscosity of the test medium

⚙️ Duration of the measurement cycle

⚙️ Selection of the correct measurement technology

With decades of experience, CAT engineers have developed extensive knowledge in balancing these variables while keeping cycle times to a minimum, ensuring both efficiency and reliability in production environments.

Flow Measurement Capabilities

⚙️ Flow Range: 0.0003 – 1800 L/min

⚙️ Pressure Range: 70 mbar – 3000 bar

⚙️ Back Pressure: Up to 500 bar

⚙️ Temperature Range: Ambient to 150°C

⚙️ Viscosity Range: 0.8 – 120 cSt

⚙️ Cycle Times: As low as 0.8 seconds per part

Why Choose CAT Flow Measurement Solutions?

✔️ Proven expertise in both liquid and air flow testing

✔️ Accurate and repeatable results across a wide range of applications

✔️ Fast cycle times for high-volume manufacturing

✔️ Bespoke systems engineered to meet specific customer requirements

CAT flow measurement systems are trusted by leading manufacturers worldwide to ensure quality, compliance, and performance.