Component Cleanliness & Flushing Rigs

Curtis Assemble & Test Ltd specialise in component cleanliness testing and flushing rigs, designed to exceed industry cleanliness standards. Using high-pressure flushing and automated processes, our systems deliver precise, repeatable results for even the most demanding applications.

Techniques for Achieving Cleanliness:

✔️ Pulsed fluid flow in alternate directions through components

✔️ CNC-controlled lances delivering high-pressure fluid at targeted points

✔️ Customised cleaning cycles refined to optimise performance by cycle time

Example Systems:

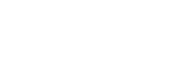

⚙️ Pump Flushing Rig – Designed to clean parts to exceed specified cleanliness levels. Flushes components with a mixture of fluid and air bubbles at pressures up to 10 bar at 5% air content. Multiple pumps can be cleaned at once to meet per-pump cycle time requirements, with fixture changes allowing a variety of pumps to be accommodated. Automatic periodic cleanliness measurement of the flushing fluid ensures required levels are maintained.

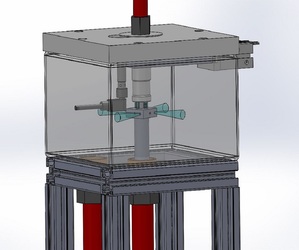

⚙️ Quick Release Connector Flushing Rig – A small, mobile rig for washing quick release fuel connectors on engine test pallets. Built with a stainless-steel power pack frame on wheels and a dedicated cleaning head. The frame houses the pumps, main tank, filters, and electrical cabinet, which contains a 4-inch HMI for basic setup and information.

⚙️ Machine Process – Quick release fittings are placed into the wash unit on a retractable fork. Sensors detect correct placement, and gripper jaws close around the component. An analogue sensor verifies correct diameter; if incorrect, the flush cycle will not begin. On completion, jaws open automatically for operator unloading. Each cleaning head includes an indicator light to display cycle status. Cycle time: approx. 10 seconds.

⚙️ High Pressure Flushing Rig – Two-station flushing machine and power pack for light duty rails. Removes internal particles using ISO 4113 liquid at high pressure. Constructed in stainless steel, making it suitable for clean room use.

Why Choose CAT Cleanliness Rigs?

✔️ Proven expertise in achieving strict cleanliness standards

✔️ Bespoke rigs designed for your specific component type

✔️ Reliable, repeatable results backed by automated monitoring

✔️ Suitable for automotive, defence, and high-precision manufacturing

Our bespoke flushing rigs and cleanliness systems ensure components meet the highest standards of cleanliness and compliance. Contact us today to discuss a tailored solution for your business.