Projects

The machine is designed to measure different aspects of 400 series diesel engines. The measurements taken are then used to select the correct thickness of head gasket and where applicable the fuel injection pump shim thickness. The machine consists of a Micro Epsilon 2060 series measurement sensor mounted on the end of a 6 axis robotic arm. The robotic arm positions the sensor in different locations around the engine when the required measurements are taken.

The machine is positioned over a production conveyor upon which any of the permissible variants of the 400 series engines arrive. Any of the engine variants can arrive in any order so the machine is capable of testing all of them without the need for a tooling change.

Once measurements have been completed the information is stored in a local SQL server database and sent to the factory MES system.

The software for the machine is designed for ease of use and clarity for production operatives, while providing advanced controls and information for experienced users within access restricted areas.

CAT produced a bespoke system that had to be retro-fitted to an already establised assembly line. It had to handle and assemble two small components delivering 8 small sub-assemblies in a 14 second cycle time.

The machine required some complex material forming and 3D printing processes were utilised to overcome this problem.

This machine is manually loaded, but fully automated. It measures the diameter and straightness of a large component over its entire length. The machine has the option to include the visual inspection of the correct screw patterns and screw presence.

Cycle time is two to five minutes with loading and unloading in addition. In excess of 1,000,000 data points can be generated and evaluated for each component.

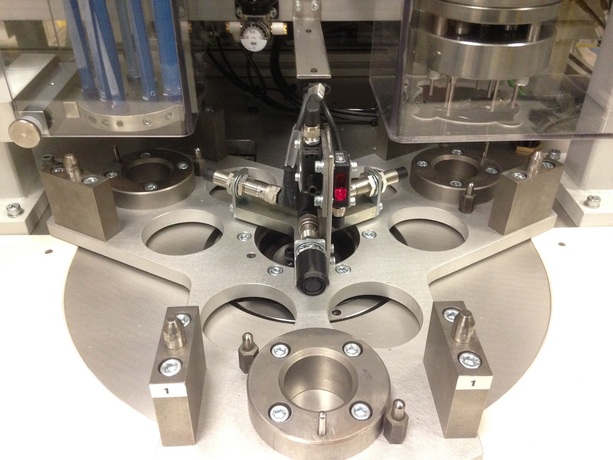

The machine assembles 2mm NCV guide and pin matched pairs, checks the assemblies for their lift measurement and finally performs two seat pressure tests and one flow test. The parts are automatically handled by a robot through the machine, from the input pallet, all the intermediate stations and back to the output pallet.

The machine has the ability to store, change, control and maintain variants of test plans. There is the facility within the software to turn off any of the main functions of the machine (assembly, lift measurement or individual hydraulic tests).

A robot loaded, automated test machine to measure the seat leakage of products.

The machine hydraulically pressurises the component to check the interface between a retained ball and the machined seat within the test component and measures leakage as pressure decay divided by time. The test pressure is stabilised nominally for five seconds (variable in software) followed by the measurement of the leak decay for 5 seconds.

A manually loaded, semi-automatic assembly aid to assist the operator and ensure that the correct number of appropriate screws are loactaed and tightened to their specified torque and angular distance.

A torque screwdriver system is integrated into the existing functioning fixture and monitored via a bespoke interface to ensure that all screws are inserted to achieve the correct number of rotations, torque and presentation.

As a manufacturer of dynamic variable flow control valves, we required a new test rig for flow performance testing to support our ongoing New Product Development programme.

Close collaboration with CAT through the specification, design and manufacture of the project has resulted in a test rig capable of flow testing up to 6 bar pressure with flow rates up to 30 litres per second for valve sizes from a ½ inch to 4 inches.

We have gained significant development advantages with total flexibility in the software operation allowing for variability of test parameters with both manual and automatic control.