Our involvement in component cleaning is primarily concerned with the internal profile.

Various techniques can be employed to achieve the cleanliness level required by the customer. Pulsing a flow of fluid in alternate directions through the component and introducing a CNC controlled lance into the component to supply high pressure fluid at precisely controlled locations are two of several techniques.

The individual make up of the component dictates the most suitable cleaning technique which we then hone and refine to give the best cleaning performance allowed by cycle time.

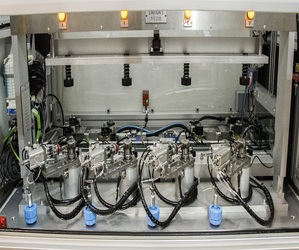

Pump Flushing Rig

The machine is designed to clean parts to exceed a specified cleanliness level. The machine flushes the parts with a mixture of fluid and air bubbles at pressures up to 10 bar at 5% air content. Multiple pumps are cleaned at once in order to achieve the required per-pump cycle time and a variety of pumps may be accommodated through fixture changes. Automatic periodic cleanliness measurement of the flushing fluid ensures it meets required cleanliness levels to clean the parts effectively.

Quick Release connector flushing rig

This small, mobile flushing rig is designed to wash quick release fuel connectors on an engine test pallet. The machine consists of two main elements, a power pack, constructed from a stainless steel frame mounted on wheels, and a cleaning head. The frame holds the pumps, main tank, filters and electrical cabinet, which houses a 4 inch HMI for basic information and setup.

Machine Process

The quick release fitting is placed into the wash unit until it sits on a retractable fork. Once in place a sensor detects the part and the gripper jaws close around the component. An analogue sensor on the gripper detects if the jaws are closed around the body in the correct position. If the jaws close onto the wrong diameter then the flush cycle will not begin. On cycle completion the gripper jaws will open ready for the operator to unload. Each cleaning head is fitted with an indicator light to inform the operator the current status of the wash. Cycle time is approximately 10 seconds.

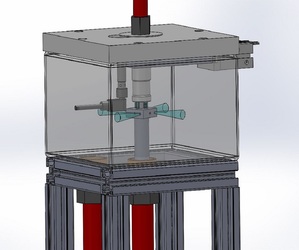

High Pressure Flushing Rig

A two-station flushing machine and power pack to accommodate a range of light duty rails, the HP flush operation removes particles inside the rail with ISO 4113 liquid. The flushing rig is constructed of stainless steel which is suitable for clean room use.