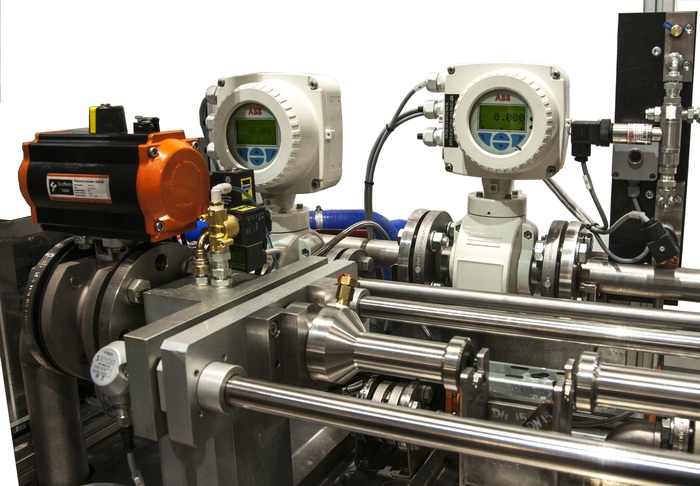

It is often difficult to determine and prove performance criteria and behaviour when developing a new product. How will it behave? How will it perform? What cycle time is necessary to ensure repeatable results? Once optimised, how to meet pre-production requirements.

Additionally, there are instances when parts are dismantled for remanufacturing. Which parts still have a useful service life thus saving money and as importantly, waste? Subcontract testing may provide the answer needed.

We have the following facilities which we can offer for prototype and pre-production testing*.

|

hydraulic pressure testing. |

Up to 3000 Bar, measurable from 0.01 cc/min up to 20cc/sec and higher. |

|

back pressure. |

Up to 500 Bar. |

|

temperature range. |

Ambient to 60°C. |

|

viscosity range. |

0.8 to 120 cSt. |

|

pressure stability. |

Better than +/-0.1 bar for steady state conditions. |

|

flow rate. |

Up to 100 l/min depending upon pressure. |

|

temperature control. |

+/-1°C depending upon fluid. |

|

evaluation criteria. |

Pressure change over time, timed pressure drop, measured flow, blob growth. |

|

measurement medium. |

Air, hydraulic oil from ambient to 150°C, calibration fluid, water. |

|

pneumatic pressure. |

Up to 250 Bar. |

|

flow range. |

0-500 L/MIN at pressures up to 3000 Bar and temperatures Up To 150°C. |

|

leak detection. |

Pressure increase or decrease over time. |

* subject to final details, quantities, agreement and timescales.