Fluid & Air Leak Detection Systems

Curtis Assemble & Test Ltd design and manufacture bespoke leak detection systems for both fluid and air applications. Our solutions accurately detect and quantify internal and external leaks across sealing faces, valves, and components. With decades of experience, we combine advanced techniques such as pressure decay, pressure rise, flow measurement, and vision inspection to deliver accurate and repeatable results for a wide range of industries.

Leak Detection Techniques

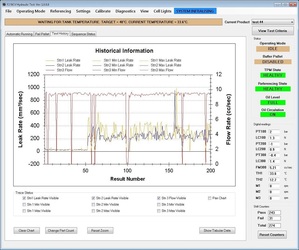

✔️ Pressure Change Methods – including pressure decay and pressure rise testing

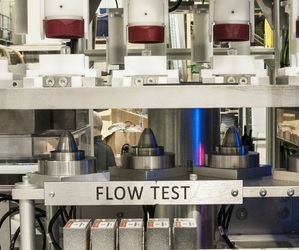

✔️ Flow Rate Measurement – using calibrated flow meters to quantify leak rates

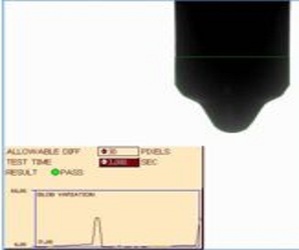

✔️ Vision Systems – optical inspection to identify external leaks where sealing is difficult

✔️ Custom Test Methods – tailored approaches based on component type, cycle time, leak rate, and medium

Leak Detection Specifications

⚙️ Test pressure: up to 3000 bar

⚙️ Temperature range: ambient to 60°C (higher options available depending on test)

⚙️ Flow range: measurable from 0.01 cc/min up to 20 cc/sec and higher

⚙️ Cycle time: from 10 seconds

⚙️ Evaluation criteria: pressure change over time, timed pressure drop, measured flow, blob growth

⚙️ Measurement medium: air, hydraulic oil, calibration fluid, water

Pressure Change Methods

-

Pressure Decay

One side of the test component is pressurised and then isolated to create a chamber at fixed pressure. Over a set period, the pressure drop is recorded, converted to a leak rate, and compared to acceptance limits. -

Pressure Rise

Both sides of the test component are sealed, with one side pressurised. Pressure increase in the unpressurised chamber is measured over time, providing a precise calculation of the leak rate.

Flow Rate Measurement

Where commercially available equipment is suitable, leaks can be quantified using flow meters. One side of the interface is pressurised, and any leak passing into a collection chamber is measured by the flow meter for accurate leak rate evaluation.

Vision-Based Leak Detection

For applications where forming a seal is impractical, vision systems can detect external leak paths. By using carefully selected lighting and optics, very small leaks can be identified and quantified.

Whether for fluid or air applications, Curtis Assemble & Test Ltd provide high-performance leak detection systems tailored to your requirements. Contact our team today to discuss a bespoke solution for your testing needs.