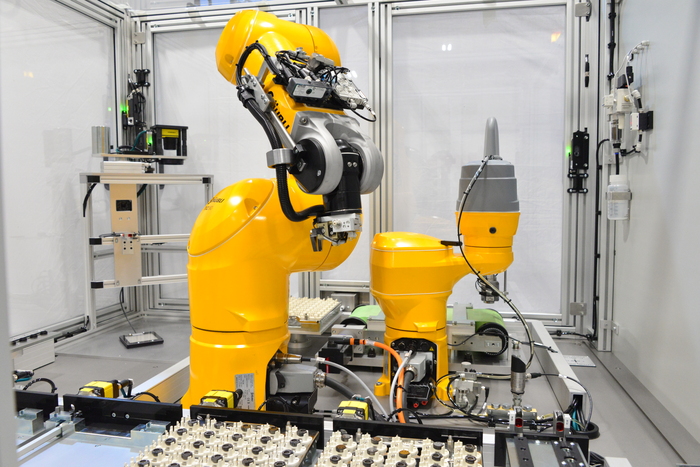

CAT have produced multiple lapping and deburring machines over the years

This machine removes a micro burr from a lapped face on automotive components. Parts are picked from input pallets and presented to a camera to check if they are the correct way up and determine the orientation of the part. The robot adjusts the orientation and flips the part if necessary as it is picked and presented to a matrix read camera before being loaded to the lapping table.

A second robot engages with the part and applies an adjustable downward force before beginning to lap the part with a figure of 8 motion. Multiple lapping steps can be defined controlling lapping radius, speed, applied load and number of laps.

Should a part fail, its associated pin is picked from the pallet using a vacuum gripper and the two are stored together in a segregated failure area.