CAT design and manufacture a range of high pressure test machines for detecting and measuring the internal and/or external leak rate in components as a means of gauging performance and quality testing.

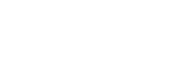

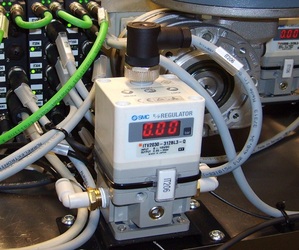

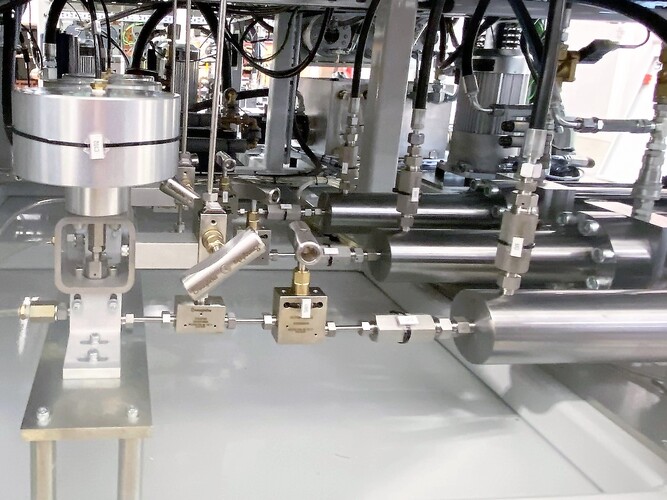

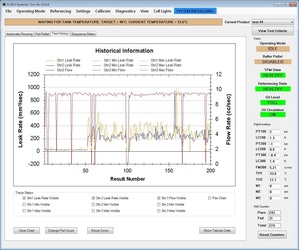

We manufacture high pressure test machines for both hydraulic and pneumatic testing using either commercially supplied equipment – for example the appropriate flow meter or a combination of pressure chamber and transducer, where the leak is monitored and compared to limits and time to produce results. As appropriate, leaks may be recorded as either pressure rise or pressure decay depending on the characteristic being monitored.

Integrated vision systems are another solution, depending on the nature of the test, where it is difficult or impractical to form a seal around the leak interface. When the leak is external and visible on the surface of the component, it may be defined by the change in the number of pixels surrounding the component in the monitored area

Leak detection specifications

| test pressure | from 70 mbar to 3000 bar |

| temperature range | ambient to 60°C depending on the type of test, but could be significantly higher |

| flow range | measurable from 0.01 cc/min up to 20cc/sec and higher |

| cycle time | from 10 seconds |

| evaluation criteria | pressure change over time, timed pressure drop, measured flow, blob growth |

| measurement medium | air, hydraulic oil, calibration fluid, water |